Sustainability

At BioLogiQ, sustainability isn’t just a buzzword- it’s a guiding principle woven into our core business. We believe that a thriving company can and should coexist harmoniously with a thriving planet.

At the heart of BioLogiQ, we understand that the choices we make today impact the world tomorrow. That’s why we strive to set a new standard for the plastics industry. Our dedication isn’t just a reflection of our values- it’s a promise to our customers, employees, and the global community.

Join us as we continue to innovate, partner for success, and improve today’s plastics for a better tomorrow. Whether it be a big leap or a baby step, every percentage of less plastic is progress towards a sustainable future.

Powered By Plants for Peak Performance

Through our patented technology, we have the ability to blend NuPlastiQ with traditional plastics, bioplastics, and recycled plastics alike. NuPlastiQ versatility means it can be mixed with a large variety of different plastic resins, allowing significant flexibility for extruders and converters to move the sustainability needle.

Additionally, NuPlastiQ added to post-consumer-recycled plastics can simplify the extrusion process and create a win-win when combined with utilizing recycled material (easier manufacturing and more recycled content).

Less virgin plastic means fewer fossil fuels, fewer pollutants, and fewer concerns for our long-term impact.

Plant-powered

NuPlastiQ® & its BioBlends®

BioLogiQ is working to improve the path to true circularity through its revolutionary plant-based 100% natural renewably sourced biopolymer called NuPlastiQ.

NuPlastiQ is the natural ally to solving the man-made problem of plastic pollution. NuPlastiQ reduces the accumulation of plastic pollution* in our environment and ocean.

NuPlastiQ is the natural ally to solving the man-made problem of plastic pollution.

Working towards making plastics sustainable

BioLogiQ’s NuPlastiQ® BioPolymer is made from annually renewable agricultural resources.

A good way to increase sustainability is to look for ways to reduce the amount of plastic and to reuse and recycle plastic products. The 3 R’s “Reduce, Reuse, Recycle” have been the focus of the plastic industry for the past decade, but that process hasn’t been successful enough, with more than an estimated 11 million tons (by PEW) of plastic estimated to reach the ocean every year.

Reduce, Reuse, and Recycle are important parts of the road to a more sustainable future, and BioLogiQ is already innovating its way to solid solutions.

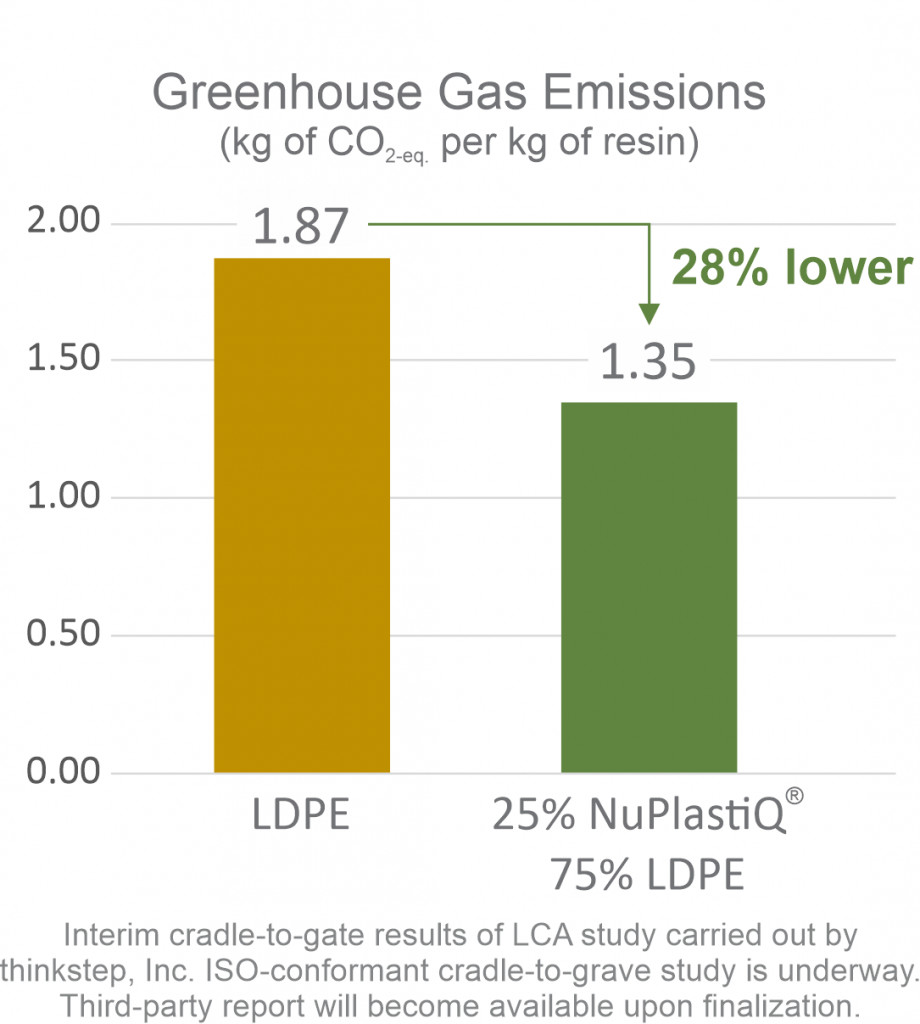

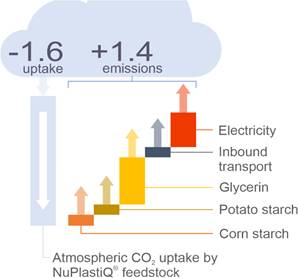

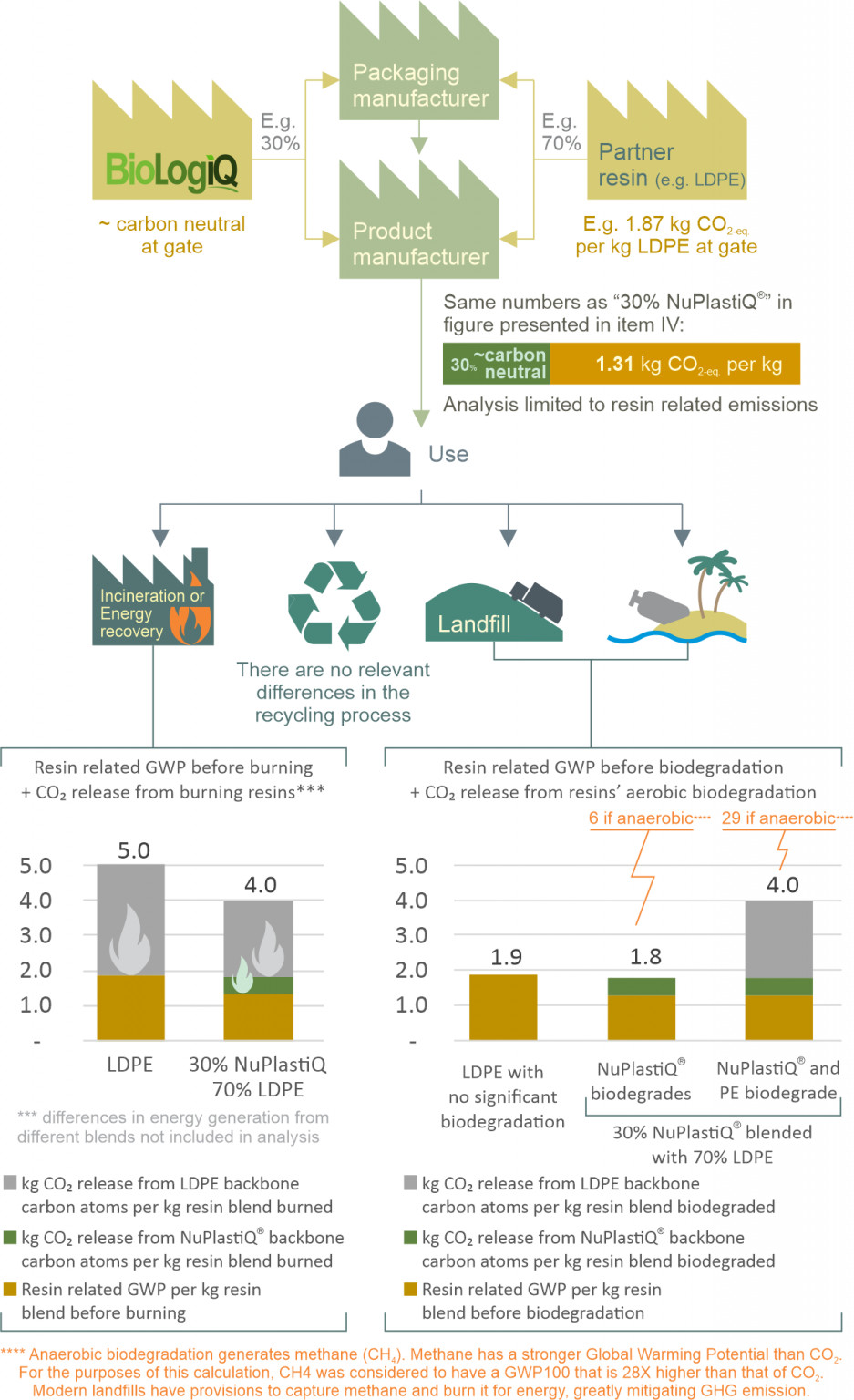

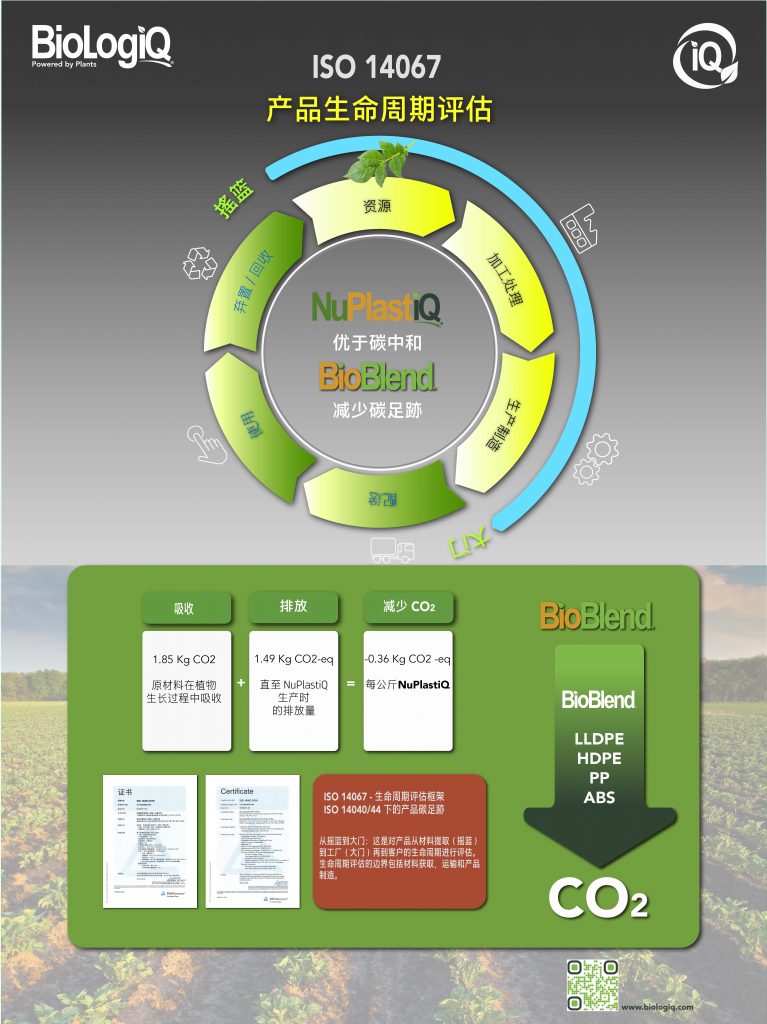

Greenhouse Gas (GHG) Savings

At BioLogiQ we are committed to preserving the quality of life we all enjoy here on the planet. Excessive reliance on fossil fuels over the past 100 years has created worldwide concerns about changes in climate, long-lived pollution, and the fact that fossil fuel, in general, is a finite resource.

We make plastic from annually renewable starch (NuPlastiQ resin) rather than petroleum to address the many valid concerns.

Mixing BioLogiQ’s NuPlastiQ BioPolymers resins with any of the petroleum-based plastic resins has dramatic and immediate effects on the carbon emissions (CO2) that ultimately affect the growing “greenhouse gas” problem. Our resins can be used as a “drop-in” replacement for a portion of polyethylene, polypropylene or polystyrene, etc. No special equipment is required for manufacturers to use our resins and there is no increase in labor costs. It simply works.

Biodegradability and Compostability

Products made with BioLogiQ’s NuPlastiQ® are durable and shelf-stable. They will not accelerate fragmentation simply because of the presence of oxygen or UV light.

BioBlend BC Resins:

NuPlastiQ will typically accelerate biodegradability of compostable resins such as PBS, PHA, PBAT or PLA, expanding the envelope of certifiable applications. In its pure form, NuPlastiQ has biodegraded as fast as cellulose under ASTM D5338 and D6691.

NuPlastiQ and several BioBlend BC grades have passed standardized tests for compostability and are certified by TUV to meet the criteria specified in ASTM D6400 and EN 13432. Some BioBlend BC grades have also passed the China Standard Biodegradability Test GB/T 19277.1-2011.

Introducing the 4th “R”

Remediation, or Bioremediation

NuPlastiQ® has been designed to help reduce the accumulation of plastic pollution* in our environment and ocean.

We are all familiar with the 3 “R’s” of the environment—Reduce, Reuse, Recycle. NuPlastiQ paves the way for a critical fourth “R” —Remediate—”The process of improving something or correcting something that is wrong, especially changing or stopping damage to the environment.” Applying remediation increases the chance that leaked plastic doesn’t persist. How?

Nature has developed a way to biodegrade durable polymers such as cellulose and lignin. Like wood, plastics may aspire to be durable and compatible with nature’s biodegradation systems. NuPlastiQ seems to enable nature to use its biodegradation toolbox in blends with PE, PP and PS. A possibility demonstrated in dozens of studies and that does not seem to be accelerating fragmentation. The addition of NuPlastiQ in PE, PP and PS can only reduce the potential for persistent microplastics accumulation in the environment.

NuPlastiQ® seems to be acting as a bioremediation trigger that enable naturally–occurring microbes to bioremediate plastics lost in the environment.

Meet EBT: Embedded Bioremediation Triggers

Copyright © 2021 BioLogiQ, Inc. All rights reserved. Although BioLogiQ, Inc. and its affiliates (“BioLogiQ”) have taken reasonable steps to ensure the accuracy of the information presented in this infographic, BioLogiQ makes no representations or warranties with respect to the information provided herein.